Bending Beam Type Loadcell

Price 15000 INR/ Unit

Bending Beam Type Loadcell Specification

- Resistance

- 350

- Theory

- Resistance Strain Gauge

- Type

- Bending Beam Type

- Accuracy

- 0.03% F.S.

- Operating Voltage

- 5~12 V DC

- Output Voltage

- 1~2 mV/V

Bending Beam Type Loadcell Trade Information

- Minimum Order Quantity

- 1 , , Unit

- Supply Ability

- 10 Units Per Month

- Delivery Time

- 2-3 Week

About Bending Beam Type Loadcell

Bending Beam Type Loadcell

Specifically designed for low profile scales and process applications, single-ended beam load cells are available in capacities ranging from 1,000 lbs up to 20,000 lbs. These load cells are constructed of tool steel as well as stainless steel. When hermetically sealed, a single ended shear beam load cell is ideal for wash down applications.

This is a Strain Gage based, single ended Shear Beam Load Cell designed for Multiple use in low profile platform scales & in tank, bin and hopper weighing systems. It is constructed from high alloy tool Steel for excellent resistance to shock and overload. The cell is sealed against moisture ingression for use in wash-down areas and it is Electro less Nickel plated for corrosion resistance. It is low cost ideal Load Cell Construction-30310-SS for industrial automation applications. This is also provided in Hardnable Stainless Steel - 17-4 PH - Model.

Features

- 100 Kgf. to 10000 Kgf. Capacities offered.

- Complete Environmental Protection -IP67 Class.

- IP68 Protection available optionally with laser welded sealing.

- Standardized output (3.0 + 0.25%) available on request.

- Low Profile Floor Scales.

- Tank, Hopper & Bag Weighing.

- Force & Tension Measurement.

- Pallet Scale.

- Industrial Automation.

- Stainless Steel version is suitable for hygienic applications like food, dairy, pharma industries & for corrosive applications like chemical industries.

High-Precision Load Measurement

The Bending Beam Type Loadcell ensures reliable and accurate readings, with a tight tolerance of 0.03% of full scale. This high level of precision makes it perfect for industrial weighing systems and research applications that demand consistency and dependability.

Durable Resistance Strain Gauge Construction

Built on established resistance strain gauge technology, the load cell delivers stable analog output signals between 12 mV/V. The rugged design and 350 resistance assure long-term use and minimal signal drift, contributing to reduced maintenance costs.

Versatile Operating Range for Diverse Applications

Designed to run on 512 V DC, this load cell accommodates various power supply scenarios. Its compact design and adaptability make it a preferred choice for professionals in industries ranging from manufacturing to logistics throughout India.

FAQs of Bending Beam Type Loadcell:

Q: How does a bending beam type load cell work?

A: A bending beam type load cell operates by converting applied force into electrical signals using resistance strain gauges. When a load is applied, the strain gauges embedded in the beam measure the resulting deformation and produce a proportional voltage output.Q: What are the main benefits of using this load cell in industrial applications?

A: Its high accuracy (0.03% F.S.), coupled with robust construction and reliable output, enables precise force measurement for quality control, automation, and process monitoring. It is also easy to integrate with standard DC supplies (512 V) and instrumentation.Q: When should I choose a bending beam load cell over other types?

A: Select a bending beam load cell when you require precise, repeatable force measurements in static or dynamic settings, especially where space is limited and installation flexibility is important.Q: Where can these load cells be sourced in India?

A: They are widely available across India from dealers, distributors, exporters, importers, manufacturers, retailers, suppliers, traders, and wholesalers specializing in industrial sensors and automation equipment.Q: What is the installation and connection process for this load cell?

A: The load cell is typically bolted into position so the force to be measured creates a bending motion. Electrical connection involves wiring to a suitable supply voltage (512 V DC) and instrument that reads the output voltage signal (12 mV/V).Q: How do I use the output signal from this load cell?

A: The output is an analog voltage proportional to the applied force. Connect the load cell to an amplifier or data acquisition system capable of reading low millivolt signals and converting them for monitoring, control, or display purposes.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Load Cell Category

Digital Load cell

Price 10000 INR / Unit

Minimum Order Quantity : 1 Unit

Type : Digital Load cell

Accuracy : 0.02% F.S.

Theory : Resistance Sensor

Resistance : 350

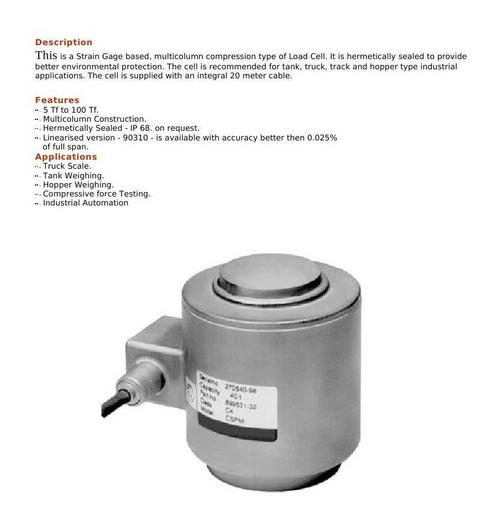

Compression Load Cells

Price 25000 INR / Unit

Minimum Order Quantity : 1 Unit

Type : Compression Load Cell

Accuracy : 0.03% of full scale

Theory : Other, Strain Gauge

Resistance : Input: 750 , Output: 700

Heavy Duty Load Cell

Price 15000 INR / Unit

Minimum Order Quantity : 1 , , Unit

Type : Heavy Duty Load Cell

Accuracy : 0.05% to 0.1% F.S.

Theory : Other, Resistance Strain Gauge

Resistance : 350 (Input and Output)

Digital Loadcell

Price 10000 INR / Unit

Minimum Order Quantity : 1 Unit

Type : Digital Loadcell

Accuracy : 0.02% F.S.

Theory : Other, Strain Gauge

Resistance : 350

GST : 07AGQPG8382B1Z8

|

SWASTIK SYSTEMS & SERVICES

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry