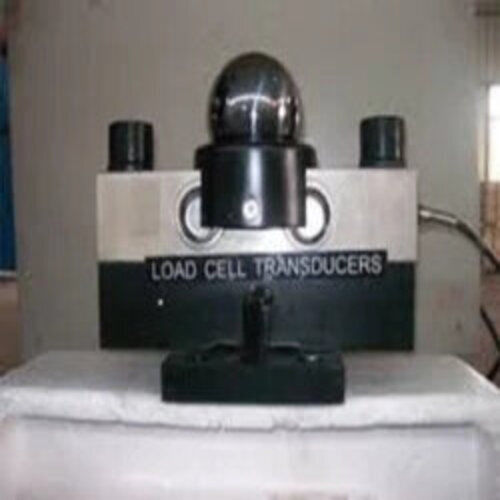

Zemic Ball type Loadcell

Price 10000 INR/ Unit

MOQ : 1 , , Unit

Zemic Ball type Loadcell Specification

- Resistance

- Input Resistance: 75010, Output Resistance: 7005

- Theory

- Resistance Strain Gauge

- Type

- Ball Type Loadcell

- Accuracy

- 0.03% F.S.

- Operating Voltage

- 5V to 15V DC

- Output Voltage

- 2.0 0.002 mV/V

Zemic Ball type Loadcell Trade Information

- Minimum Order Quantity

- 1 , , Unit

- Supply Ability

- 10 Units Per Month

- Delivery Time

- 2-3 Week

About Zemic Ball type Loadcell

Shear Beam type Loadcell

Specifically designed for low profile scales and process applications, single-ended beam load cells are available in capacities ranging from 1,000 lbs up to 20,000 lbs. These load cells are constructed of tool steel as well as stainless steel. When hermetically sealed, a single ended shear beam load cell is ideal for wash down applications.

This is a Strain Gage based, single ended Shear Beam Load Cell designed for Multiple use in low profile platform scales & in tank, bin and hopper weighing systems. It is constructed from high alloy tool Steel for excellent resistance to shock and overload. The cell is sealed against moisture ingression for use in wash-down areas and it is Electro less Nickel plated for corrosion resistance. It is low cost ideal Load Cell Construction-30310-SS for industrial automation applications. This is also provided in Hardnable Stainless Steel - 17-4 PH - Model.

Features

Specifically designed for low profile scales and process applications, single-ended beam load cells are available in capacities ranging from 1,000 lbs up to 20,000 lbs. These load cells are constructed of tool steel as well as stainless steel. When hermetically sealed, a single ended shear beam load cell is ideal for wash down applications.

This is a Strain Gage based, single ended Shear Beam Load Cell designed for Multiple use in low profile platform scales & in tank, bin and hopper weighing systems. It is constructed from high alloy tool Steel for excellent resistance to shock and overload. The cell is sealed against moisture ingression for use in wash-down areas and it is Electro less Nickel plated for corrosion resistance. It is low cost ideal Load Cell Construction-30310-SS for industrial automation applications. This is also provided in Hardnable Stainless Steel - 17-4 PH - Model.

Features

- 100 Kgf. to 10000 Kgf. Capacities offered.

- Complete Environmental Protection -IP67 Class.

- IP68 Protection available optionally with laser welded sealing.

- Standardized output (3.0 + 0.25%) available on request.

- Low Profile Floor Scales.

- Tank, Hopper & Bag Weighing.

- Force & Tension Measurement.

- Pallet Scale.

- Industrial Automation.

- Stainless Steel version is suitable for hygienic applications like food, dairy, pharma industries & for corrosive applications like chemical industries.

Highly Accurate Force Measurement

With an accuracy of 0.03% F.S., the Zemic Ball Type Loadcell is suited for applications requiring precise weight monitoring. The resistance strain gauge theory ensures consistency and reliability, making it an excellent choice for industries where minute discrepancies can affect operations.

Versatile Compatibility and Operation

Operating at 5V to 15V DC, this loadcell is compatible with standard industrial equipment. Its input and output resistances are optimized for stability and effective signal response, facilitating quick integration in a range of weighing and automation systems.

FAQs of Zemic Ball type Loadcell:

Q: How is the Zemic Ball Type Loadcell typically installed in industrial settings?

A: The loadcell is mounted beneath weighing platforms or machinery, allowing for accurate force or weight detection. Its ball-type design facilitates even load distribution and simplifies alignment during installation.Q: What specific applications benefit most from this loadcell?

A: Industries such as manufacturing, logistics, and material handling utilize this loadcell for weighing scales, batching systems, and force measurement tasks where high accuracy and reliability are crucial.Q: When should resistance strain gauge-based loadcells like this be selected over other types?

A: Select resistance strain gauge loadcells when your application demands precise, repeatable measurement with minimal drift, especially in tasks involving process control or trade-approved weighing.Q: Where can I purchase the Zemic Ball Type Loadcell in India?

A: You can source this loadcell through authorized dealers, distributors, and suppliers, as well as from exporters and importers across India. Many manufacturers and wholesalers also offer direct procurement channels for bulk or specialized orders.Q: What is the process for integrating this loadcell into an existing weighing system?

A: Integration involves securely mounting the loadcell, wiring it to a suitable indicator or data acquisition system, ensuring the supplied voltage is between 5V and 15V DC, and calibrating the setup for precise readings.Q: How does the output voltage specification impact data accuracy and system selection?

A: The output voltage of 2.0 0.002 mV/V ensures highly stable and precise signal output corresponding to applied loads. This helps in selecting compatible instrumentation and amplifiers for optimal system performance.Q: What are the primary benefits of using the Zemic Ball Type Loadcell in industrial operations?

A: It delivers high precision, robust durability, and adaptability, supporting efficient weighing, improved process control, and reduced operational errors in various industries.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Load Cell Category

double beem load cell

Price 10000 INR / Number

Minimum Order Quantity : 1 Number

Theory : Other, Resistance Strain

Output Voltage : 2.0 mV/V 0.1 mV/V

Resistance : Input: 390 15, Output: 350 3

Accuracy : 0.03% F.S.

Digital Load cell

Price 10000 INR / Unit

Minimum Order Quantity : 1 Unit

Theory : Resistance Sensor

Output Voltage : 5V/12V (as per model)

Resistance : 350 ohms

Accuracy : 0.02~0.05%

Digital Loadcell

Price 10000 INR / Unit

Minimum Order Quantity : 1 Unit

Theory : Other, Strain Gauge

Output Voltage : 5 VDC

Resistance : 350

Accuracy : 0.02% F.S.

Digital Load cell

Price 10000 INR / Unit

Minimum Order Quantity : 1 Unit

Theory : Resistance Sensor

Output Voltage : 5V DC

Resistance : 350

Accuracy : 0.02% F.S.

SWASTIK SYSTEMS & SERVICES

GST : 07AGQPG8382B1Z8

GST : 07AGQPG8382B1Z8

A-12/3, Hardevpuri 100 Feet Road, Shahdara, Delhi - 110093, India

Phone :91-89203-23592

Mr Dayanand Gupta

(Managing Director)

Mobile :+919810895623, +919599388861, +918448313665

|

SWASTIK SYSTEMS & SERVICES

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry