Labman Rotational Viscometer LMDV-60

Price 72000 INR/ Unit

Labman Rotational Viscometer LMDV-60 Specification

- Weight

- 8.5 kg

- Dimension (L*W*H)

- 475 x 380 x 330 mm

- Power

- 50 W

- Color

- White

- Voltage

- 220 V 10%, 50 Hz

- Usage

- Measurement of viscosity of fluids

- Application

- Laboratory, Research, Industrial Viscosity Testing

- Material

- Metal Body with Plastic Panel

- Capacity

- 10-2,000,000 mPas

- Product Type

- Rotational Viscometer

- Operate Method

- Digital Control with Touch Keys

- Classification

- Laboratory Instrument

- Model

- LMDV-60

- Accuracy

- ±1% of F.S.

- Speed Range

- 0.3 to 60 RPM (Selectable)

- Spindle Types

- Standard set of 4 spindles (No. 1-4)

- Temperature Display

- Yes (Sensor Optional)

- Display Type

- Large LCD Display

- Repeatability

- ±0.5% of F.S.

- Power Supply

- AC 220V/110V, 50/60Hz

- Protection

- Overload Protection

- Data Output

- RS232 Interface

- Auto Stop Function

- Yes

- Measuring Range

- 10~2,000,000 mPa·s

Labman Rotational Viscometer LMDV-60 Trade Information

- Minimum Order Quantity

- 1 Unit

- Payment Terms

- Letter of Credit (L/C), Letter of Credit at Sight (Sight L/C), Paypal, Cash Against Delivery (CAD), Cash in Advance (CID), Cheque

- Supply Ability

- 10 Units Per Month

- Delivery Time

- 3 Days

- Sample Available

- Yes

- Sample Policy

- Contact us for information regarding our sample policy

- Main Export Market(s)

- Australia, North America, Eastern Europe, Africa, Middle East, South America, Asia

- Main Domestic Market

- All India

About Labman Rotational Viscometer LMDV-60

Labman Rotational Viscometer LMDV-60

Approx Price: Rs 74,000 / Number

Minimum Order Quantity: 1 Number

Product Details:

| Power | Electric |

| Standard | ISO certified |

| Material | Steel |

| Display | Digital |

| Screen | LCD |

Digital Rotational Viscometer use the idea that the torque required to turn an object in a fluid is a function of the viscosity of that fluid. They measure the torque required to rotate a disk or bob in a fluid at a known speed.

DIGITAL ROTATIONAL VISCOMETER

STANDARD FEATURES

- Big Ultra Bright Backlight LCD Display

- Direct reading on Display

- Auto Range function

- Temperature display

- Printer & Computer Interface

- Data Logger Software (Optional)not applicable in WDV- 8

Digital Direct Reading Rotational Viscometer

Wensar WDV series is Rotational Digital Direct Reading Viscometer to measure absolute viscosity of Newton Liquids as well apparent viscosity of non Newton liquid featured by high flexibility reliable Test result, easy operation and good appearance.

Common Specifications

- Data Displayed

- Selected Speed

- Selected Spindle

- Viscosity Reading

- Torque Percentage

- Temperature

Advanced Display and Control

The large LCD display allows operators to easily monitor viscosity readings and operational parameters. The digital control interface with touch keys ensures intuitive setup and operation, reducing the risk of user error and enhancing workflow efficiency.

Versatile Viscosity Measurement

With a measuring range from 10 to 2,000,000 mPas and four standard spindles, the LMDV-60 can analyze fluids of varying thickness in laboratory, research, and industrial settings. The selectable speed between 0.3 and 60 RPM allows users to tailor measurements for optimal accuracy.

Reliable Operation and Safety Features

Auto stop functionality, overload protection, and high repeatability provide consistent, safe results during continuous testing. Optional temperature sensor allows for accurate adjustment and monitoring of temperature-dependent viscosity properties.

FAQs of Labman Rotational Viscometer LMDV-60:

Q: How do I set up and operate the Labman LMDV-60 Rotational Viscometer?

A: Simply connect the viscometer to a suitable AC power source (220V/110V, 50/60Hz), choose the appropriate spindle (No. 1-4) for your sample, and use the touch keys to set the desired speed. The large LCD display guides you through all operational steps for smooth and intuitive measurement.Q: What types of fluids can be measured using the LMDV-60 viscometer?

A: The LMDV-60 can measure fluids with viscosity ranging from 10 to 2,000,000 mPas. This includes oils, gels, creams, industrial lubricants, paints, and more, making it suitable for laboratory, research, and industrial applications.Q: When is it beneficial to use the optional temperature sensor feature?

A: The temperature sensor is advantageous when precise viscosity measurements are required under specific thermal conditions. It enables accurate temperature display and control, ensuring that temperature-dependent viscosity properties are accounted for during testing.Q: Where are Labman LMDV-60 viscometers commonly used in India?

A: This instrument is widely utilized in laboratories, research institutions, and industrial settings across India for viscosity testing, quality assurance, product development, and process monitoring by manufacturers, exporters, suppliers, and traders.Q: What process should be followed to ensure accurate viscosity measurements?

A: To achieve optimal results, select the correct spindle, adjust the speed appropriately, and ensure the sample is stable in temperature (especially when using the optional sensor). Regularly calibrate the device and use the auto stop function to maintain measurement precision and consistency.Q: How does the auto stop function benefit users during viscosity testing?

A: The auto stop feature halts the measurement process automatically upon completion or in case of overload, protecting the instrument and sample. This reduces the risk of data errors and extends the instruments operational life.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Scientific & Laboratory Instrument Category

Digital stainless steel Ultrasonic Cleaner

Price 68000 INR / Number

Minimum Order Quantity : 1 Number

Dimension (L*W*H) : 550330360 Millimeter (mm)

Weight : 18 Kilograms (kg)

Color : white

Product Type : labman

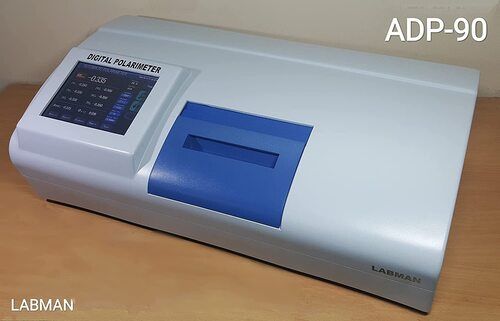

Automatic Digital Polarimeter ADP90

Price 380000 INR / Number

Minimum Order Quantity : 1 Number

Dimension (L*W*H) : 850 x 470 x 380 Millimeter (mm)

Weight : 35kg Kilograms (kg)

Color : white

Product Type : labman

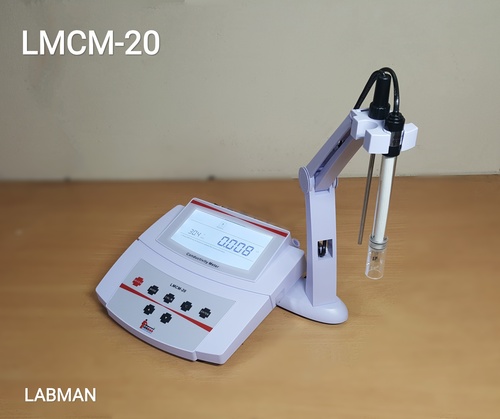

labman Conductivity Meter

Price 16500 INR / Number

Minimum Order Quantity : 1 Number

Dimension (L*W*H) : 210 205 75mm Millimeter (mm)

Weight : 2 Kilograms (kg)

Color : white

Product Type : labman

DIGITAL VISCOMETER LABMAN

Price 65000 INR / Number

Minimum Order Quantity : 1 Number

Dimension (L*W*H) : 400 x 350 x 360 Millimeter (mm)

Weight : 10 Kilograms (kg)

Color : white

Product Type : Digital Viscometer

GST : 07AGQPG8382B1Z8

|

SWASTIK SYSTEMS & SERVICES

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry