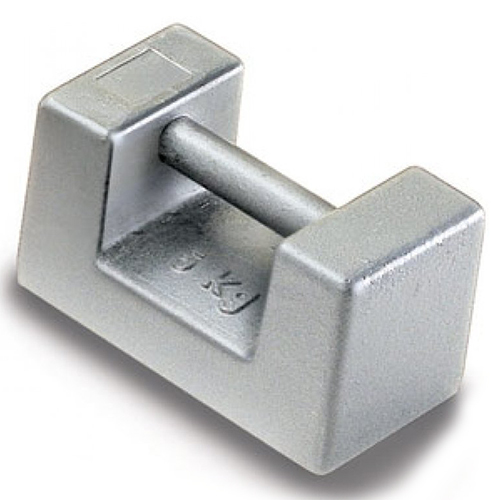

Calibration Analytical Weights

Price 15000 INR/ Number

Calibration Analytical Weights Specification

- Resolution

- Depends on weight set; up to 0.1 mg

- Pressure Range

- Atmospheric only

- Equipment Type

- Calibration Analytical Weight

- Protection

- Supplied in protective case, corrosion-resistant finish

- Humidity %

- Recommended below 65% RH

- Temperature Range

- 10C to 40C (recommended operating range)

- Diameter

- Varies by mass; typically from 3 mm to 45 mm

- Measurement Range

- 1 mg to 500 g

- Application Media

- Solid (used for calibration of balances and scales)

- Capacity

- 500 g (maximum weight in set)

- Material

- Stainless Steel

- Accuracy

- High Precision (as per OIML Class E1/E2/F1/F2 standards)

- Range

- 1 mg to 500 g (as per available weight sets)

Calibration Analytical Weights Trade Information

- Minimum Order Quantity

- 1 Number

- FOB Port

- North East Delhi

- Payment Terms

- Cash Advance (CA), Cash in Advance (CID)

- Supply Ability

- 2 Per Week

- Delivery Time

- 3 Week

- Main Domestic Market

- All India

About Calibration Analytical Weights

Laboratory Measuring Weights offered is made available in stainless steel finish.

Specifications

-

Density option of 7.90kg/dm3

-

Having magnetic susceptibility of 0.05

-

Coming with nominal value of 1mg-20kg

-

Construction finish coming with cavity for adjustment

-

Available in shape options of flake in weight range of 1mg-500mg and cylindrical in weight range of 1g-20kg

-

Choice of mirror polish finish

Specifications

-

OIML R 111-1 Edition 2004 (E)

-

Accuracy class: E1 & E2

-

Construction: Solid single piece fabrication

Precision Calibration for Laboratory Excellence

These analytical weights are designed specifically for the calibration of high-precision laboratory balances. With their adherence to OIML Class E1, E2, F1, and F2 standards, users can trust the accuracy and reliability these weights provide. The stainless steel construction, combined with a corrosion-resistant finish and non-magnetic properties, ensures stable mass and dependable long-term performance, making them perfect for sensitive measurements in scientific and industrial labs.

Tailored to Meet Diverse Laboratory Needs

From single weights to complete sets ranging from 1 mg to 500 g, our calibration analytical weights accommodate a broad spectrum of calibration requirements. Available in various shapes, including cylindrical, knob, wire, and sheet types, and packaged in protective, foam-lined boxes, they address any calibration scenario. Each weight is clearly marked by laser engraving or stamping, ensuring easy identification and traceability.

FAQ's of Calibration Analytical Weights:

Q: How should I properly handle and maintain calibration analytical weights?

A: To maintain the accuracy and integrity of calibration analytical weights, always use lint-free cloths for cleaning and avoid direct handling by using gloves or tweezers. Store the weights in their foam-lined box when not in use to protect them from contamination and physical damage.Q: What is the recommended environment for using these analytical weights?

A: Optimal use of these weights is achieved in controlled environments with temperatures between 10C to 40C, humidity below 65% RH, and atmospheric pressure. These conditions help preserve the precision and prevent corrosion.Q: When should I recalibrate or check my calibration weights?

A: Recalibration intervals depend on use frequency, regulations, and laboratory protocols. As a general guideline, weights should be checked and recalibrated at least annually, or more frequently if used extensively or after accidental drops.Q: Where are these weights commonly used?

A: These calibration analytical weights are typically used in laboratories, research institutions, and quality control settings across industries such as pharmaceuticals, education, food, and manufacturing, wherever highly precise balance calibration is required.Q: What are the benefits of using OIML E1, E2, F1, F2 class calibration weights?

A: Utilizing OIML-calibrated weights ensures high precision, traceability, and compliance with international metrology standards, guaranteeing accurate results in critical measurements and audits.Q: How are the weights identified and protected during storage and use?

A: Each weight features laser-engraved or stamped markings for clear identification and traceability. Protective foam-lined boxes are provided to safeguard against scratches, corrosion, and environmental contamination during storage and handling.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Measuring Weights Category

SS F1 Class Weight Box

Price 15000 INR / Number

Minimum Order Quantity : 1 Number

Material : Stainless Steel (SS), Nonmagnetic

Calibrated Weight

Price 15000 INR / Unit

Minimum Order Quantity : 1 , , Unit

Product Type : Measuring Weight

Color : Grey

Material : Cast Iron

Brass Knob Type Weights

Price 10000 INR / Unit

Minimum Order Quantity : 1 Unit

Product Type : Measuring Weights

Color : Silver

Rectangular Slotted Weights

Price 4000 INR / Unit

Minimum Order Quantity : 1 Unit

Product Type : Measuring Weights

Color : Grey

GST : 07AGQPG8382B1Z8

|

SWASTIK SYSTEMS & SERVICES

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry