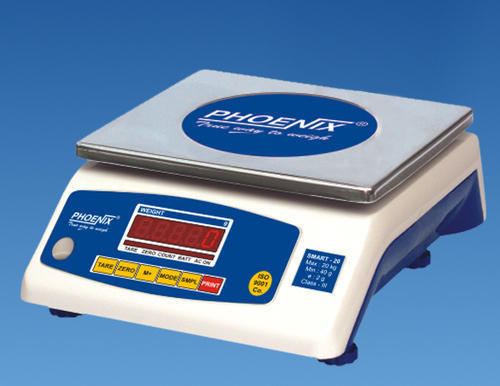

Load Indicators

Price 10000 INR/ Unit

Load Indicators Specification

- Automatic Grade

- Automatic

- Size

- Standard

- Interface

- RS-232 Serial

- Usage

- Heavy Industrial Loads

- Function

- Weight Measurement

- Features

- Overload Alarm, High Accuracy, User Friendly Interface

- Power Source

- AC Electric

- Connectivity Type

- Wired

- Display Type

- Digital

- Battery Life

- Up to 8 Hours (Optional)

- Application

- Industrial Weighbridges, Crane Scales, Material Handling

- IP Rating

- IP65

- Product Type

- Load Indicator

- Weighing Scale Type

- Electronic Weighing Indicator

- Material

- Mild Steel

- Power Supply

- 220V AC / 50Hz

- Monitor Display

- 7 Digit LED

- Load

- Up to 60 tons

- Accuracy

- +/- 1% FS

- Capacity Range

- 1 ton to 60 tons

- Color

- Grey / Black

Load Indicators Trade Information

- Minimum Order Quantity

- 1 , , Unit

- Supply Ability

- 10 Units Per Month

- Delivery Time

- 2-3 Week

About Load Indicators

A load indicator is a device that measures and displays the amount of load or weight being applied to a particular structure or machine. This device is commonly used in engineering and construction to ensure that structures and machines are not overloaded beyond their safe operating limits. It comes in various forms depending on the applications. It accurately measures the weight or load being applied and provides a real-time reading of the load. Load indicator can also be equipped with alarm and warning system to alert users if the load exceeds safe limits.

Reliable and Versatile Industrial Weighing Solution

Designed for heavy-duty environments, this weighing indicator delivers accurate weight measurements for loads up to 60 tons. Its automatic operation, user-friendly interface, and overload protection make it ideal for industrial weighbridges, crane scales, and large-scale material handling. The unit combines durability with precision, ensuring consistent performance in challenging conditions.

Easy Integration and Data Management

With flexible panel mounting, RS-232 serial connectivity, and internal memory storage, the device streamlines integration into existing industrial systems. Its digital calibration and straightforward controls further simplify setup and maintenance, while secure data archiving protects important weight records for future use.

FAQs of Load Indicators:

Q: How do I install this load indicator in my industrial system?

A: Panel mounting is required for this load indicator. Simply secure the unit into a standard control panel opening and connect it to a compatible load cell via mV/V input. Detailed wiring and setup instructions are provided to ensure reliable integration with your existing weighing systems.Q: What are the primary benefits of using this weighing indicator for heavy loads?

A: The weighing indicator offers high accuracy (+/- 1% FS) for weights up to 60 tons, rapid response time, and a robust IP65-rated enclosure. Its overload alarm and internal memory help protect your equipment and streamline operational data management, making it suitable for demanding industrial applications.Q: Where can this load indicator be used?

A: This device is ideal for use in industrial weighbridges, crane scales, and material handling systems. Its wide temperature range, humidity tolerance, and rugged design make it suitable for factories, warehouses, ports, and various heavy industrial environments.Q: What is the process for calibrating the load indicator?

A: Digital calibration is provided. Follow the calibration instructions in the user manual, typically involving connecting a reference weight, entering calibration mode through the interface, and storing the calibration data digitally for precise measurement.Q: How does the internal memory function and when should I use it?

A: The load indicator features built-in memory capable of storing up to 999 records. This is especially beneficial when tracking historical load data, conducting audits, or ensuring traceability of weighed materials over time.Q: What is the maximum battery life and is it suitable for continuous operation?

A: The device offers up to 8 hours of optional battery-powered operation, making it suitable for short-term use during power interruptions. For continuous operation, connect the indicator to a standard 220V AC, 50Hz power supply.Q: How does the overload alarm work and what is its benefit?

A: The unit includes a relay output that triggers an alarm in the event of overload conditions. This feature helps prevent equipment damage and ensures operator safety by alerting users when the load exceeds preset thresholds.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Weight Indicators & Controllers Category

Height Weight

Price 60000 INR / Unit

Minimum Order Quantity : 1 , , Unit

Product Type : Weighing Scale

Monitor Display : Digital

Power Supply : Electric

Weighing Scale Type : Other

Weighing Controller

Price 10000 INR / Unit

Minimum Order Quantity : 1 Unit

Product Type : Weighing Scale

Monitor Display : Digital

Power Supply : Electric

Table Top Display

Price 5000 INR / Unit

Minimum Order Quantity : 1 , , Unit

Product Type : Weight Scale

Monitor Display : Digital

Power Supply : Electric

Weighing Scale Type : Mechanical Scale

Load Indicators

Price 10000 INR / Unit

Minimum Order Quantity : 1 Unit

Product Type : Weighing Scale

Monitor Display : Digital

Power Supply : Electric

GST : 07AGQPG8382B1Z8

|

SWASTIK SYSTEMS & SERVICES

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry