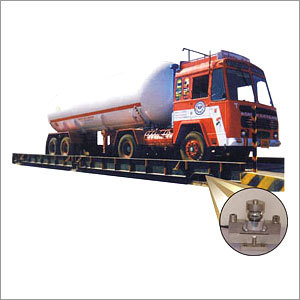

Pitless Type Weigh Bridge

Price 450000 INR/ Unit

MOQ : 1 , , Unit

Pitless Type Weigh Bridge Specification

- Color

- Blue & Gray

- Power Supply

- Single Phase

- Material

- Mild Steel Platform

- Structure

- Modular, Heavy Duty Steel

- Display Type

- Digital LED Indicator

- Loading Capacity

- Up to 120 Tons

- Accuracy

- 0.05% of FSD

Pitless Type Weigh Bridge Trade Information

- Minimum Order Quantity

- 1 , , Unit

- Supply Ability

- 10 Units Per Month

- Delivery Time

- 2-3 Week

About Pitless Type Weigh Bridge

Pitless Type Weigh Bridge

This type of weighbridge / Truck scale is most suitable where the excavation work for foundation is difficult or construction of pit is expensive. Since the structure is above ground level, vehicles can approach the weighbridge only from two directions where the ramps are provided. This type of weighbridge requires more space.

Benefits

This type of weighbridge / Truck scale is most suitable where the excavation work for foundation is difficult or construction of pit is expensive. Since the structure is above ground level, vehicles can approach the weighbridge only from two directions where the ramps are provided. This type of weighbridge requires more space.

Benefits

- Costly Pit construction is eliminated.

- Platform above ground level- No water logging during rainy season

- Problem of pit maintenance is eliminated.

- Easy maintenance since all parts accessible above ground level.

- In Pitless weighbridge RCC ramp work must be required atleast 3 meters for both side for easy movement of vehicle.

Efficient Truck Weighing Solution

This pitless type weigh bridge eliminates the need for extensive pit construction, making it easier and faster to install on-site. Intended for surface mounting, it is ideal for a variety of settings, including industrial, logistics, and transport facilities. The modular steel structure offers high durability and supports a broad range of vehicle sizes, all while maintaining reliable, precise results every time.

Reliable and Durable Build Quality

Constructed with a heavy-duty mild steel platform and protected load cells (IP68 rated), this weigh bridge is engineered to withstand harsh environments. The robust structure is designed for high-volume and heavy-load operations, ensuring longevity with minimal maintenance. Digital calibration with an overload protection system adds an extra layer of safety to daily use.

User-Friendly Operation & Connectivity

The bridge features a clear digital LED indicator and operates in multiple weighing modesgross, tare, and net. Seamless PC integration is facilitated through RS232 or RS485 interfaces, optimizing workflow for data management and reporting. Its intuitive controls make it accessible for operators, enhancing efficiency in busy truck weighing and logistics operations.

FAQs of Pitless Type Weigh Bridge:

Q: How is the pitless type weigh bridge installed?

A: This weigh bridge is surface-mounted, requiring no pit excavation. Its modular structure allows for straightforward and rapid installation on prepared, level ground, reducing set-up time and associated construction costs.Q: What are the main benefits of using a pitless type weigh bridge for truck weighing?

A: The pitless design simplifies maintenance, avoids water accumulation issues, and enables easy access to components. Its digital calibration and overload protection system ensure reliable, accurate measurements and enhance operational safety.Q: When should I calibrate the weigh bridge?

A: Calibration is recommended during installation and periodically, as specified in the manufacturers guidelines or after heavy use. The bridge supports digital calibration, making the process efficient and precise.Q: Where can this weigh bridge be used?

A: Designed for versatility, it can be installed at industrial plants, logistics hubs, truck depots, warehouses, and manufacturing units, providing dependable weighing for trucks and heavy vehicles.Q: What interface does the weigh bridge offer for computer connectivity?

A: It comes equipped with RS232 and RS485 interfaces, allowing seamless connection to PC systems for data recording, monitoring, and management.Q: How accurate is the weigh bridge, and what is its weighing capacity?

A: The bridge offers high accuracy at 0.05% of full scale deflection (FSD) and is capable of weighing loads up to 120 tons, accommodating even the heaviest trucks in the industry.Q: What is the process for using the weigh bridge in gross, tare, and net modes?

A: Vehicles can be weighed fully loaded (gross), then unloaded (tare), and the system will automatically calculate the net weight. The digital LED display provides clear readings throughout each weighing process.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Electronic Weighbridge Category

Pit Type Weigh Bridge

Price 450000 INR / Unit

Minimum Order Quantity : 1 , , Unit

Material : Mild Steel

Structure : Rugged Modular Platform

Display Type : Digital

Loading Capacity : Up to 150 Tons

SWASTIK SYSTEMS & SERVICES

GST : 07AGQPG8382B1Z8

GST : 07AGQPG8382B1Z8

A-12/3, Hardevpuri 100 Feet Road, Shahdara, Delhi - 110093, India

Phone :91-89203-23592

Mr Dayanand Gupta

(Managing Director)

Mobile :+919810895623, +919599388861, +918448313665

|

SWASTIK SYSTEMS & SERVICES

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry